Tamaki Co., Ltd. can use plastic resin processing equipment to help develop new products.

|

TAMAKI MFG.CO.,LTD. We will meet the needs of ourcustomers with reliabletechnology for more than 50years since our founding. |

|

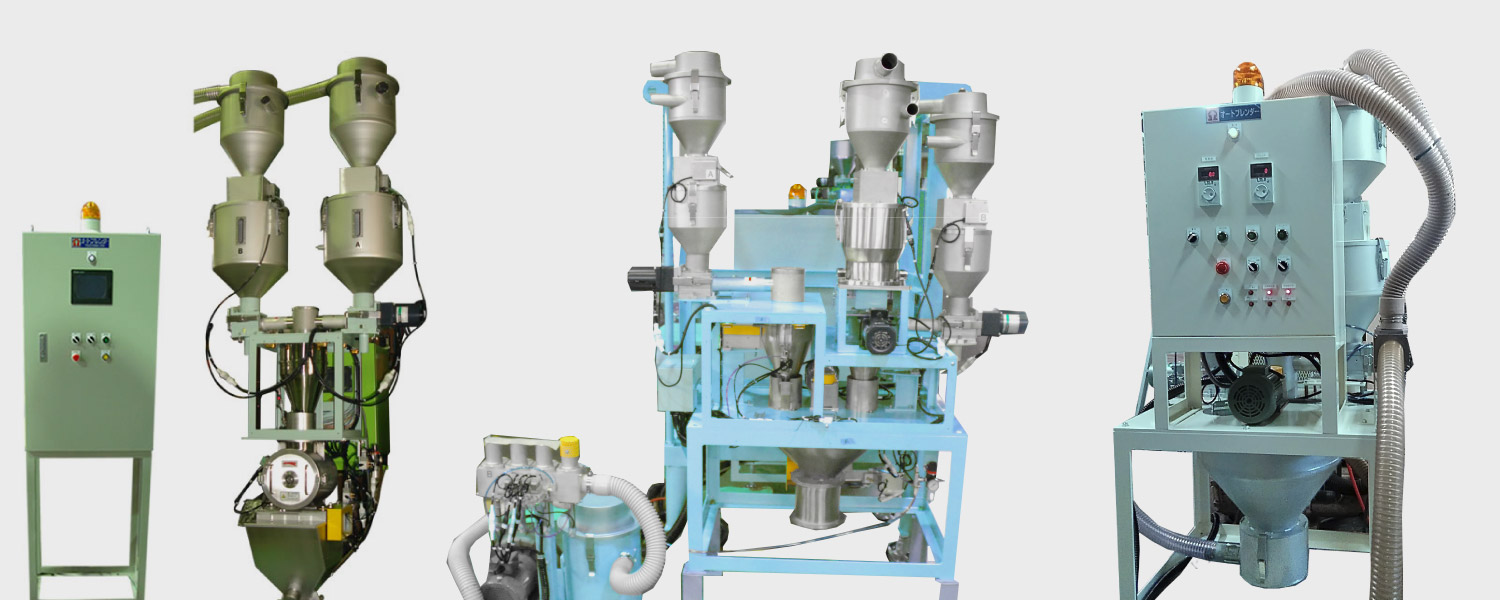

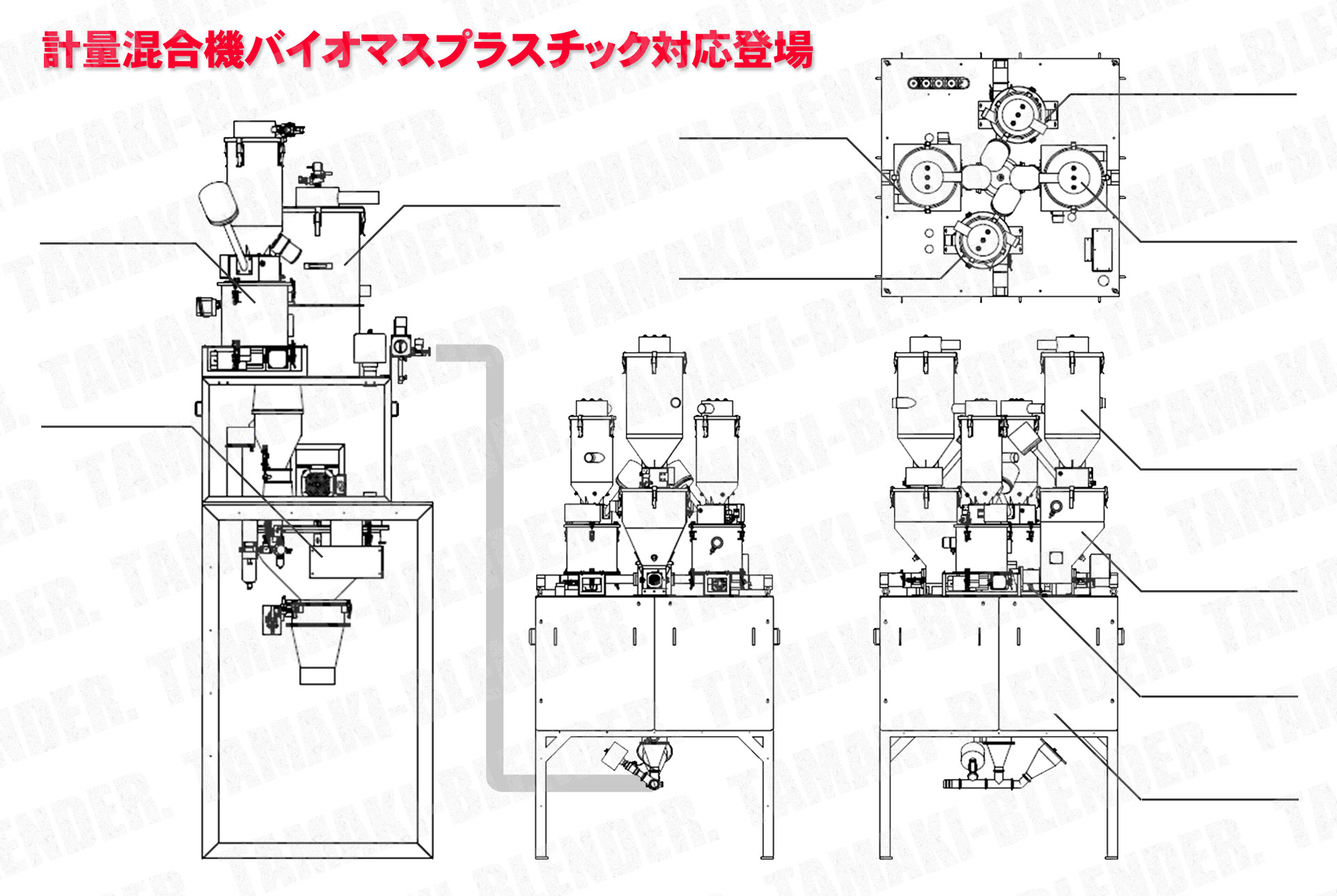

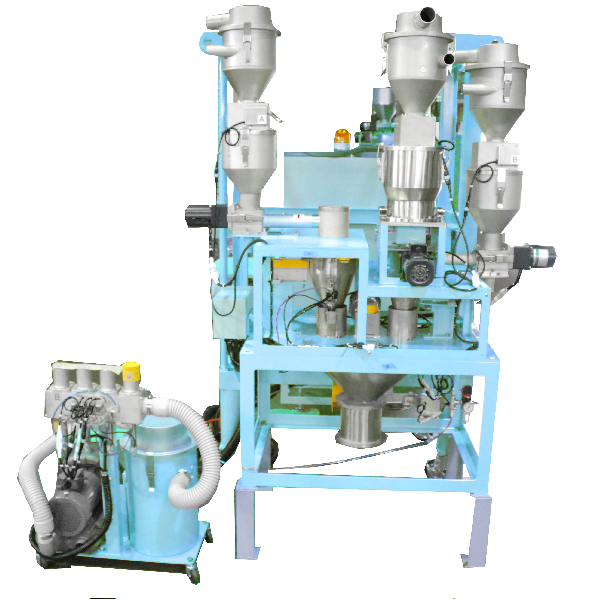

Powder measuring mixer (mixer)

We measure and mix materials such as pellets, powders, crushed materials, and liquids in the plastics, medical products, metallurgical, and food industries. We have realized our own measuring system and ease of use for a wide variety of combinations, from large plants to lab level. We can flexibly respond to the site.This device measures and mixes pellets, pigments, liquids, additives, crushed materials, etc. in a fixed amount, and is indispensable for reducing raw material costs and automating coloring processes. Tamaki's powder measuring and mixing machines are top-class in terms of precision measuring technology and mass coloring.

Materials that cannot be transported Material transfer Mixing Tank Biomass materials Additives, etc. Main material MB materials, etc. Material Suction Loader Material Hopper Material Feeder Material metering |

|||||||

Biomass plastics, a renewable organic resource, are gaining attention

Tamaki's technological capabilities, capable of measuring and mixing anything from pellets and powders to liquids, support manufacturing companies in tackling environmental issues. |

|||||||

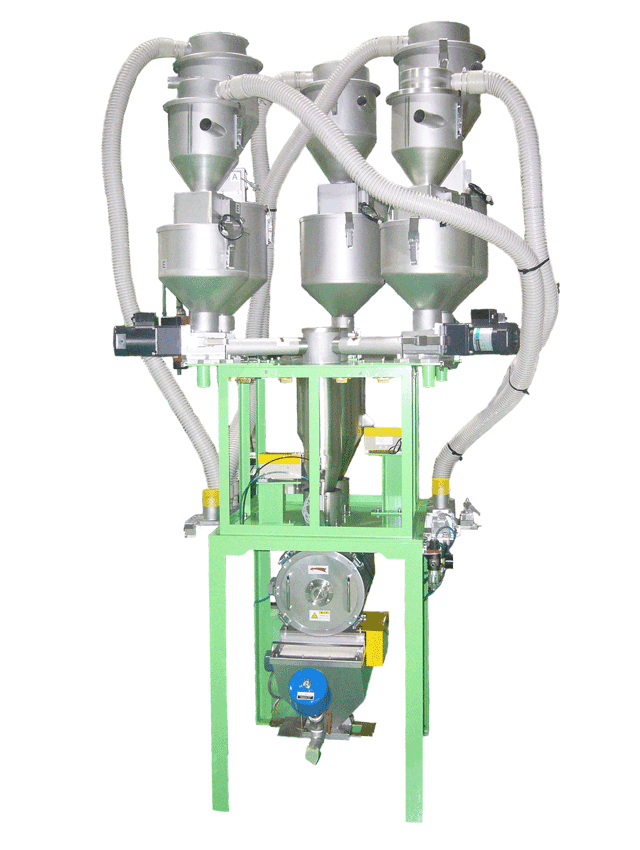

Any material can be weighed and mixed

Tamaki's weighing machines can weigh and mix the materials used in extruders, inflation molding machines, injection molding machines, etc. to create products with extreme precision.An example of materials that can be weighed and mixed

| Super engineering plastic | Daily necessities, building materials, packing materials, etc. | Engineering plastics, home appliances, gears and bearings |

|

|

|

Auto blender (automatic weight weighing and coloring blender)

|

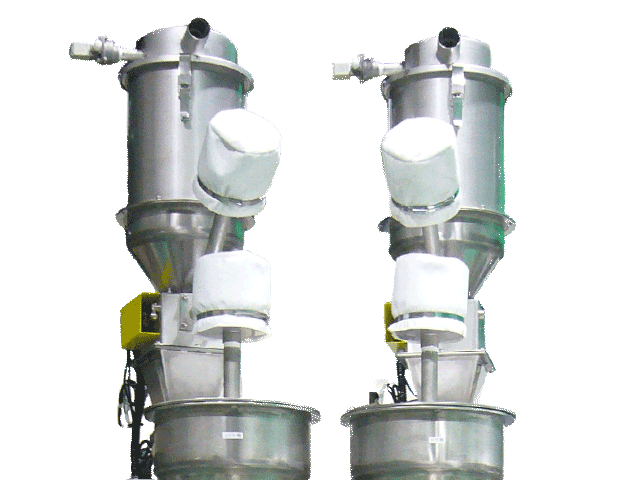

From the storage hopper section, several types of special feeders receive the raw materials to be cut out into the weighing section, and the load cell that has a built-in load cell detects the increase or decrease in the amount and weighs it. We help you improve work efficiency with excellent functions and operability, such as easy operation with a touch panel, measurement sensitivity of 1 / 20,000, and measurement error detection correction for external shocks.

Automatic weight weighing coloring blenderWeigh the materials in the load cell and mix. There are few weighing errors due to the shape and size of the material, and more accurate weighing is possible compared to the capacity weighing type. |

|

Features of auto blender

|

|

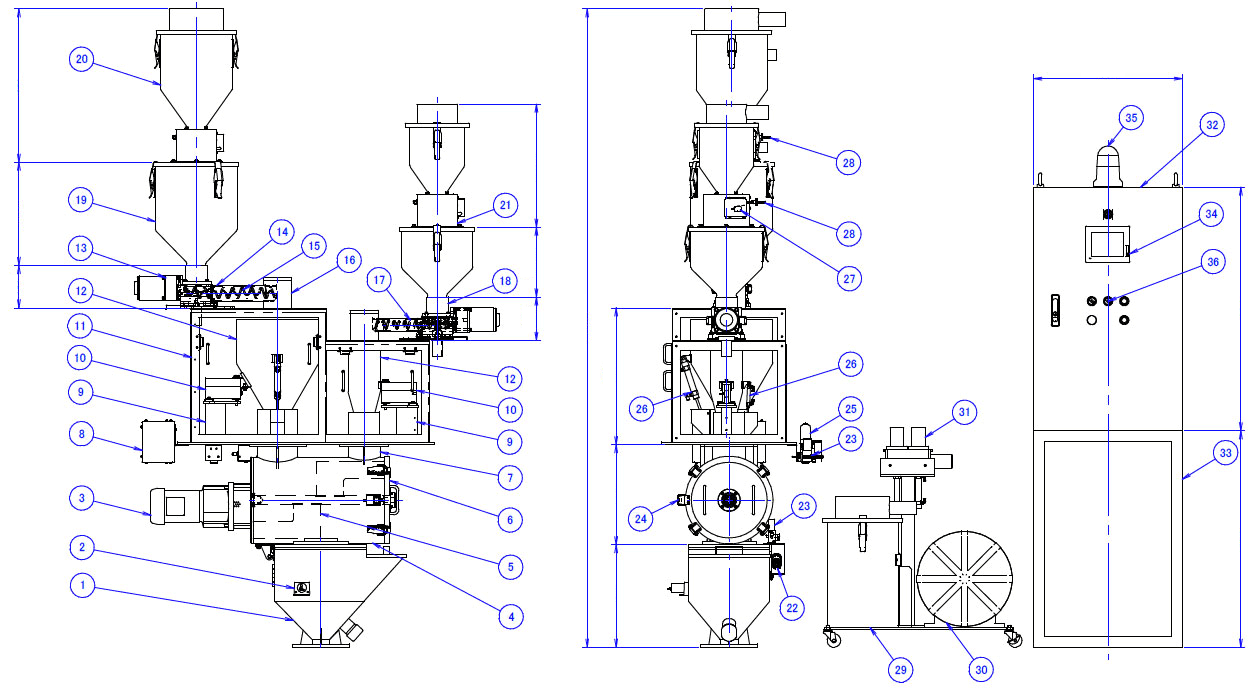

Weighing Blender lines

| TACOM-80D type | TACOM-100SF type |

|

|

|

|

Part name

|

Part name

|

specification

| MODEL | LC15K | LC10K | LC7K | LC5K | LC2K | LC1K |

| Power consumption | AC200V / 100V |

|||||

| Electric motor | 750W | 400W | 400W | 200W | 90W | 90W |

| Air pressure | 3-5kg / cm3 | |||||

| Weighing display | Touch panel | |||||

| Installation area | 1500 x 500 mm | 1500 x 600mm | 1400 x 1000mm | 1000 x 1000mm | 1000 x 750mm | 800 x 800mm |

| height | 2000mm | 2400mm | 2400mm | 2350mm | 2250mm | 1500mm |

| Body weight | 250kg | 220kg | 220kg | 200kg | 170kg | 130kg |

We are happy to accept factory tours

At Tamaki, which researches and develops blender, we are happy to accept factory tours.Introduction of newly developed and new products

|

In addition, we have created an agitator that matches the characteristics of the material so that the material inside the material hopper does not solidify when using a powdery material with high adhesiveness.

At Tamaki, we conduct a powder material characteristic confirmation test in advance, determine the parts requirements such as the hopper shape, motor, screw, and agitator according to the characteristics, and start the design. If you bring materials such as powder and pellets, you can try the in-factory test for free.

Original production and customization by combining with other models is also possible according to your company's request. We will design a mixer according to your factory equipment.