|

TAMAKI MFG.CO.,LTD. We will meet the needs of ourcustomers with reliable technologyfor more than 50 years since ourfounding. |

|

Product Info

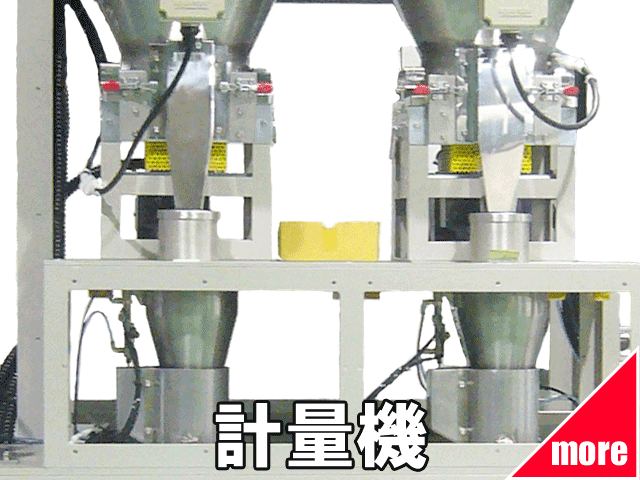

Weighs and blends materials such as pellets, powders and crushers. For diversifying formulations, we have realized a unique weighing system and usability from large plants to lab level. We respond flexibly to the site.| Raw material transport | Weighing machine | Blender |

| Continuous weighing machine | Hand sealer | Custom order |

Tamaki's long-loved products

|

Due to the discontinuation ofproduction of electrical parts and theexhaustion of dedicated boards, wecannot respond to failures.

A large amount of capital investment isrequired to purchase a new machine.

Do you have any problems such as?

We can update the hooder motor screw and control panel of the weighing unit to a new type of digital control. You can solve your worries for about half the price of a new installation. The loader, hopper, etc. can be used as they are, and at the same time, the equipment is cleaned and calibrated by the manufacturer, so products with stable quality can be continuously manufactured.

Product Line

It is a list of the main products manufactured by Tamaki Co., Ltd. Customization and special original production are also possible according to your request.Hand sealer |

|||

For hand sealer barrier |

|||

For hand sealer poly |

Overview of Tamaki's system line

| raw materials | ||||||||||

|

Automatic raw material transportationRealize automation from manual input |

|||||||||

| Storage hopper | ||||||||||

|

PN hopper loaderUses high-performance free timing damper |

|||||||||

| Various original feeder parts | ||||||||||

|

Special feedercoil |

|

||||||||

| Weighing unit | ||||||||||

|

Automatic calculation method by load cell detection bysetting the measurement valueHigh lightweight accuracy and weighing sensitivity of 1 / 20,000 |

|||||||||

| Mixing part | ||||||||||

|

Mixer auto blenderDrum type (horizontal type) / Hopper type (vertical type) |

|||||||||

| Stock tank and molding machine | ||||||||||

Contract system

Tamaki Co., Ltd. accepts the design and manufacture of various power-saving equipment according to the customer's request.Zero line (powder and granular material measuring device)

It is a device that cuts out with a feeder and continuously weighs batches in an extremely short time.

Since the strength can be switched, the amount of drop into the measuring cup is suppressed to a very small amount,

You can be sure to secure the desired weighing value.

In addition, since the vibration of the machine during operation is controlled, it is possible to detect the measured value with extremely high accuracy.Semi-automatic batch weighing machineBy automating the manual bagging work, the physical burden on the worker is reduced, and highly efficient and stable bagging work is realized.

CPU material consumption printer, etc.

When making the same thing using the same data, the amount of material consumed for each printer is calculated to unify the material consumption and reduce the waste of material.

PN hopper loader

A high-performance damper for transporting raw materials.

Demonstrates excellent suction ability by completely maintaining reliable operability and airtightness in the hopper.

Loss-in weight (subtraction weighing machine)

If you want to weigh a small amount, subtract the weight cut out from the original weight and perform accurate weighing.

We can design powders, crushed materials, and pellets with specifications that match the raw materials.