Raw material transportation equipment

We transport materials such as pellets, powders, and crushers in the plastics industry, medical products industry, metallurgical industry, food industry, etc. It supports diversifying line configurations from raw material silos to directly above the molding machine.

Raw material transport are the basis of factory automation. It is required to transport materials efficiently and without waste in a limited space. Also, by combining with other models, it can be designed and realized with your factory layout.

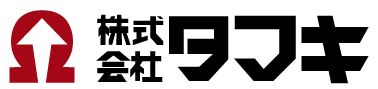

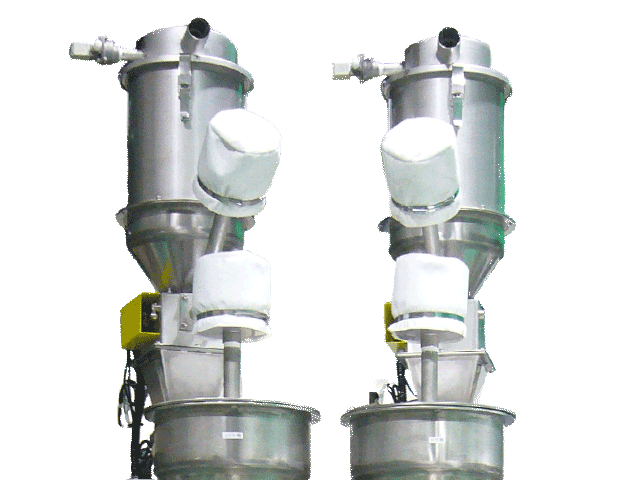

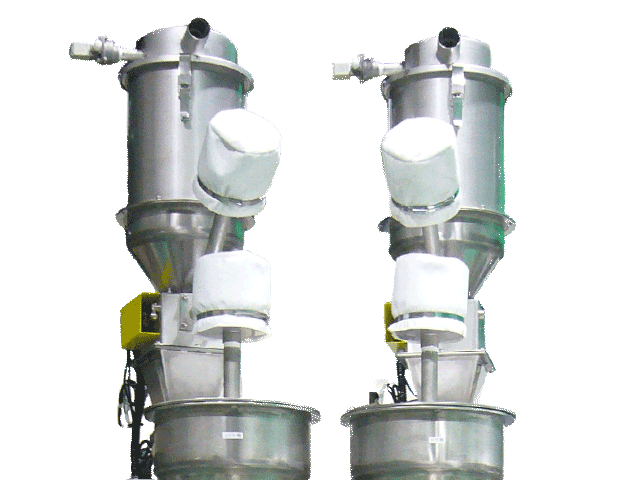

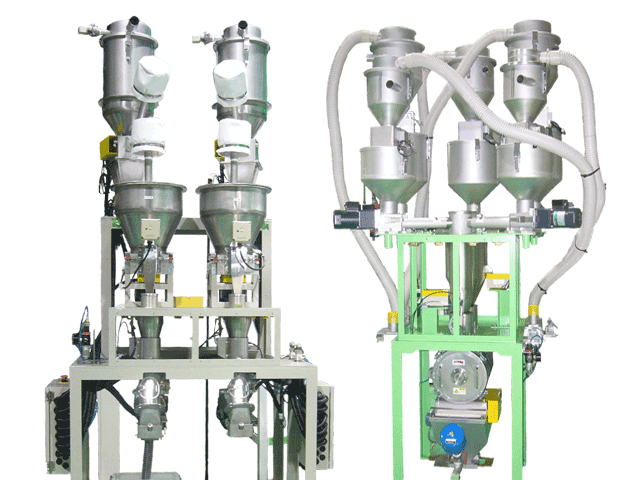

PN hopper loader (raw material transportation device)

The PN Hopper Loader is a high performance damper that we have completed after a long period of rigorous experimentation. It provides reliable operability, completely maintains the airtightness inside the hopper, and has excellent suction capacity.

Achieve reliable raw material transportationSeparate fine powder with the cyclone hopper of the main body! Furthermore, the dust collector cyclone separates the dust. It provides reliable operability, completely maintains the airtightness inside the hopper, and has excellent suction capacity.

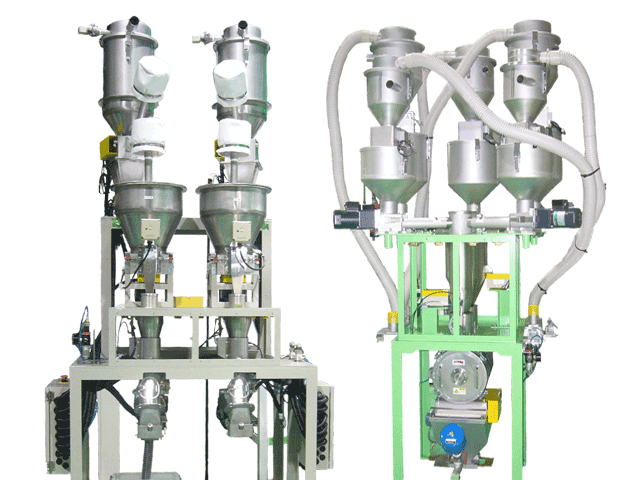

We also offer a "multi-loader" that enables continuous centralized operation by connecting several or more hopper loaders.

|

|

Features of PN hopper loader

- The free timing damper operates reliably without being affected by the biting of materials that occurs during suction operation, completely maintains the airtightness inside the hopper, and demonstrates excellent suction capacity.

- The suction amount can be set using the touch panel.

- The cyclone hopper of the hopper loader body separates the fine dust, and the dust collector cyclone separates the dust.

|

|

| Hopper loader connection |

|

| We also have a "multi-loader" that allows continuous centralized operation by connecting several or more hopper loaders. |

|

| Fully automated |

|

| By using it directly with the auto blender TACOM series, completely unmanned operation is possible. |

|

| Streamlining material transportation |

|

| It is very effective in transporting granules and crushed materials in various fields such as plastics, chemicals, foods, and metallurgy. |

|

Raw material transportation equipment product list

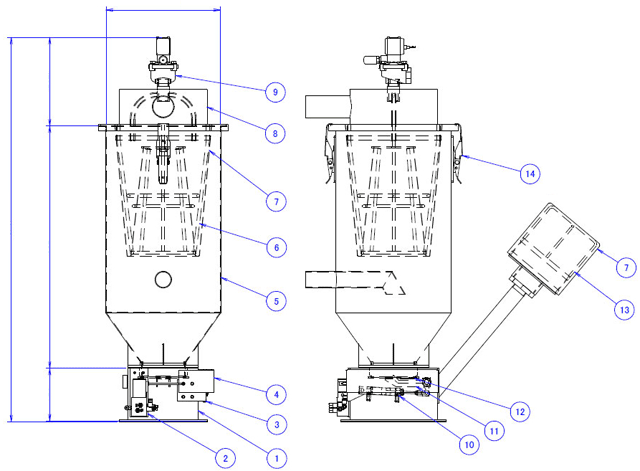

PN hopper loader

PN-N-MS-TYPE |

PNP hopper loader (for powder)

PNP-N-MS-TYPE Separate type |

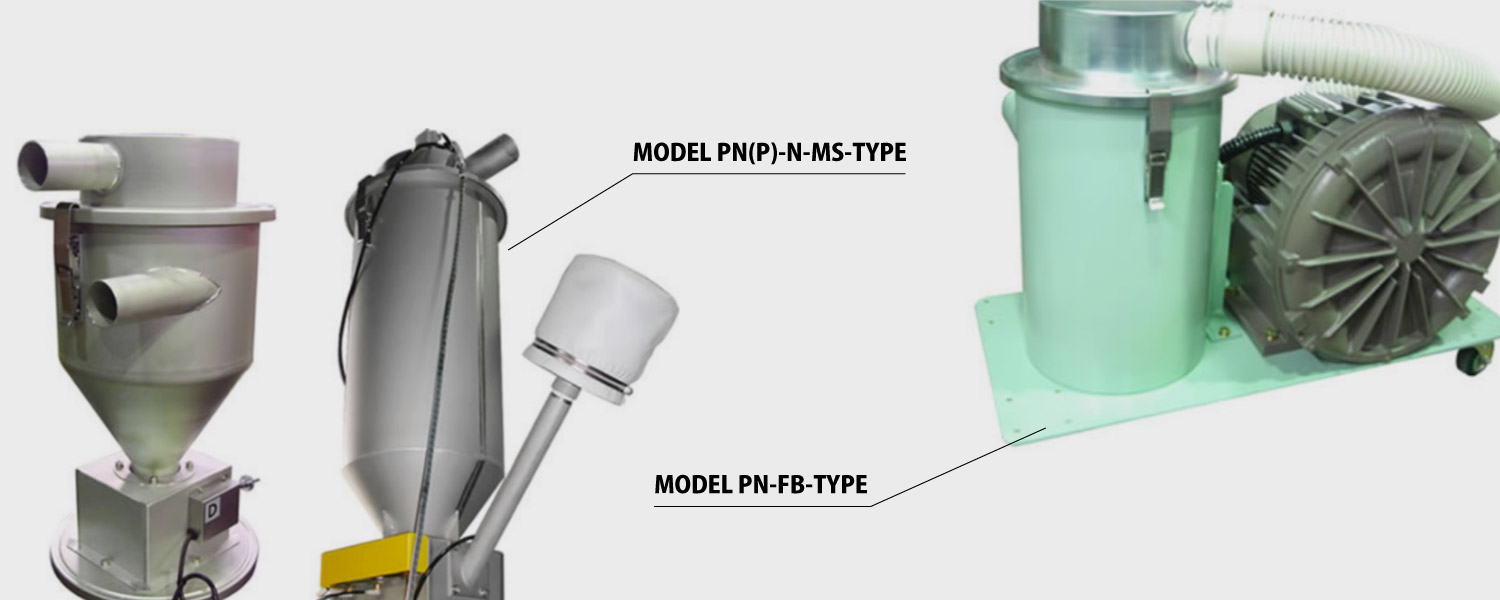

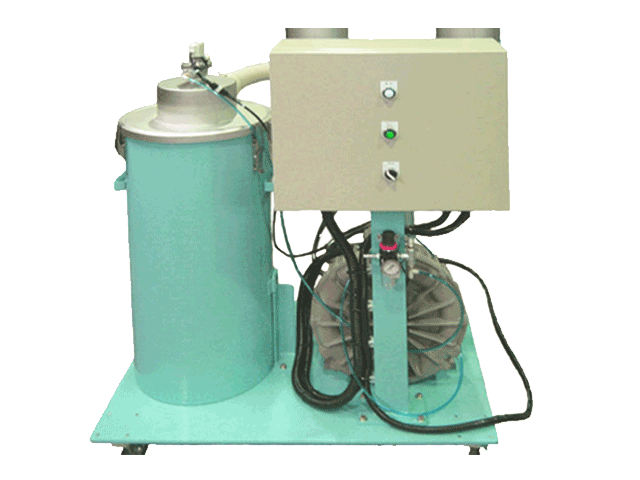

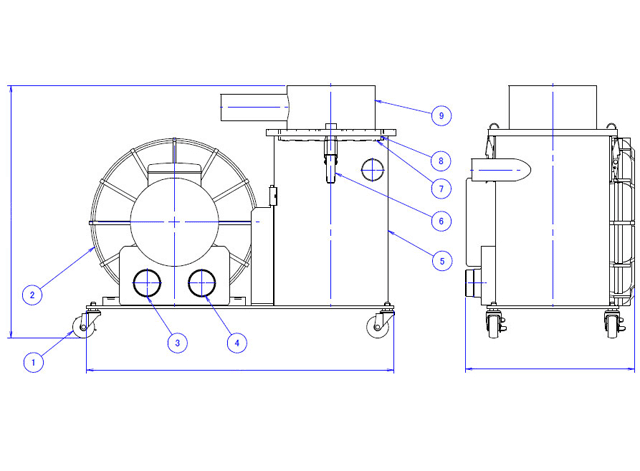

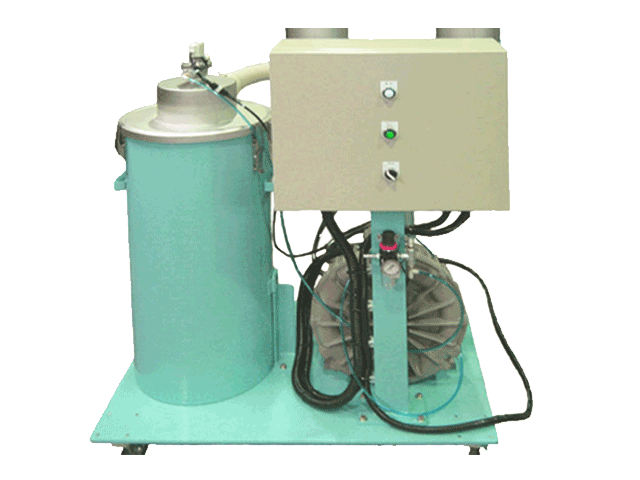

Blower unit

PN-FB (SB) -TYPE |

|

|

|

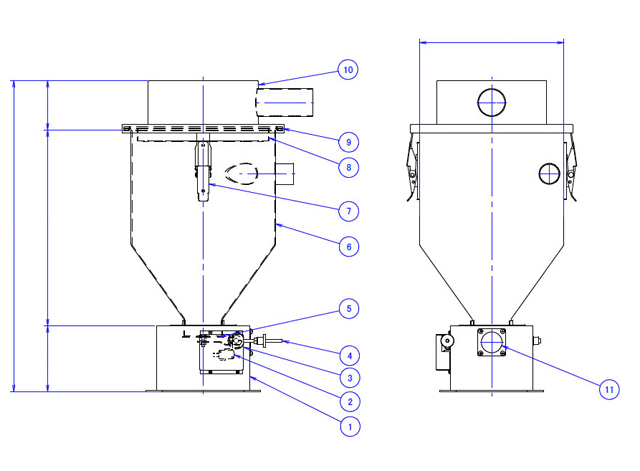

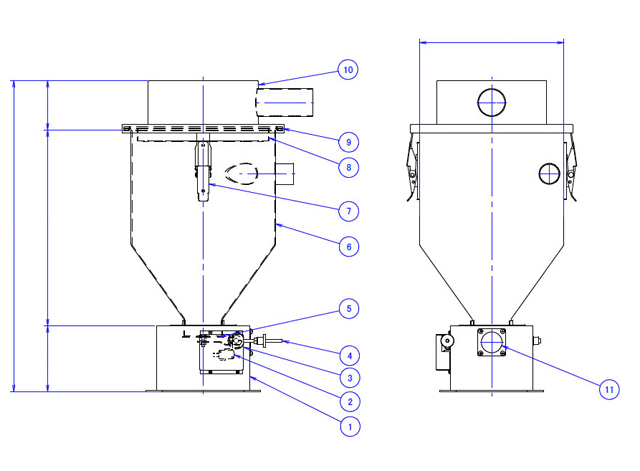

Part name

- Damper case

- Microswitch

- Switch cover

- Balancer

- Damper plate

- Cyclone hopper

- Catch grip

- Net filter

- Groove rubber packing

- Hopper lid

- Air vent hole

|

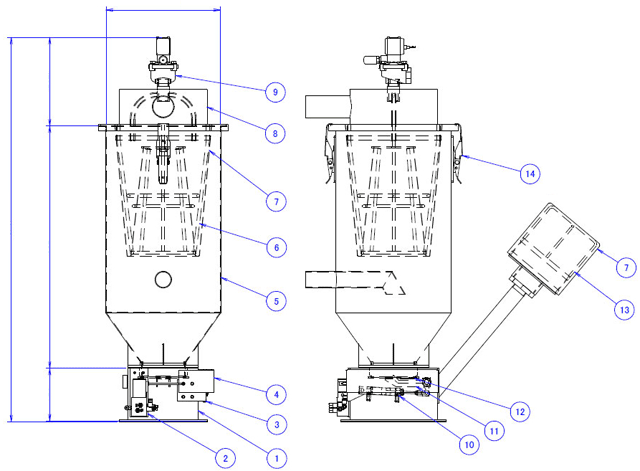

Part name

- Damper case

- Air cylinder solenoid valve

- Cylinder bracket

- Cylinder cover

- Cyclone hopper

- Filter frame

- filter

- Hopper lid

- Solenoid valve for air purging

- Solenoid valve for air cylinder

- Damper arm

- Damper plate

- Air bleeding filter

- Catch clip

|

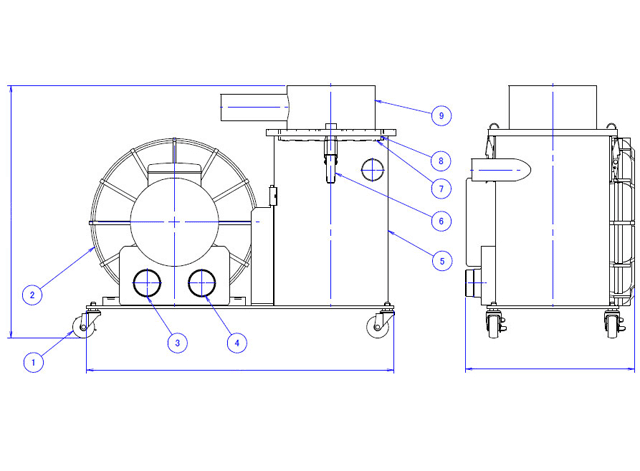

Part name

- caster

- Blower

- Suction port

- Discharge port

- Dust collector

- Catch clip

- Net filter

- Filledon filter

- Hopper lid

|

specification

|

Power consumption |

AC200V / 100V 50 / 60Hz |

| Electric motor |

0.55 / 0.85kw, 1.3 / 1.9kw, 2.3 / 3.4kw, 3.3 / 5.0kw |

| Transport capacity |

150kg, 200kg, 400kg, 600kg, various |

Original production and customization by combining with other models is also possible according to your company's request. We will design the entire raw material transportation device according to your factory layout.