Tamaki Co., Ltd. can use plastic resin processing equipment to help develop new products.

|

TAMAKI MFG.CO.,LTD. We will meet the needs of ourcustomers with reliabletechnology for more than 50years since our founding. |

|

Zero line (powder material weight weighing device)

|

With Tamaki's powder and granular material weighing machine, the weighing deviation value can always be kept constant (on the 0 line).

Any material can be weighed

Tamaki's weighing machines can weigh materials used in extruders, inflation molding machines, injection molding machines, etc., with extreme precision.An example of materials that can be weighed

| Super engineering plastic | Daily necessities, building materials, packing materials, etc. | Engineering plastics, home appliances, gears and bearings |

|

|

|

Zero line features

|

First, a large amount of material is transferred, and when about 90% of the total measurement is transferred, the amount is automatically switched from a large amount to a small amount, and the amount of drop from the feeder to the measuring cup is suppressed to a very small amount to ensure the desired measurement value. can.

In addition, since machine vibration during operation is controlled, extremely accurate measurement value detection (deviation value 0) is possible, and at the same time continuous measurement movement is possible.

Zero line features

|

|

Zero line series of powder and granular material weight weighing machines

| Model name | Overview |

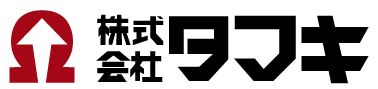

| Zero line TFP-RF-TYPE | A material weighing machine equipped with a table / rotary feeder to measure the weight of fine powder, dry color, and tanker. |

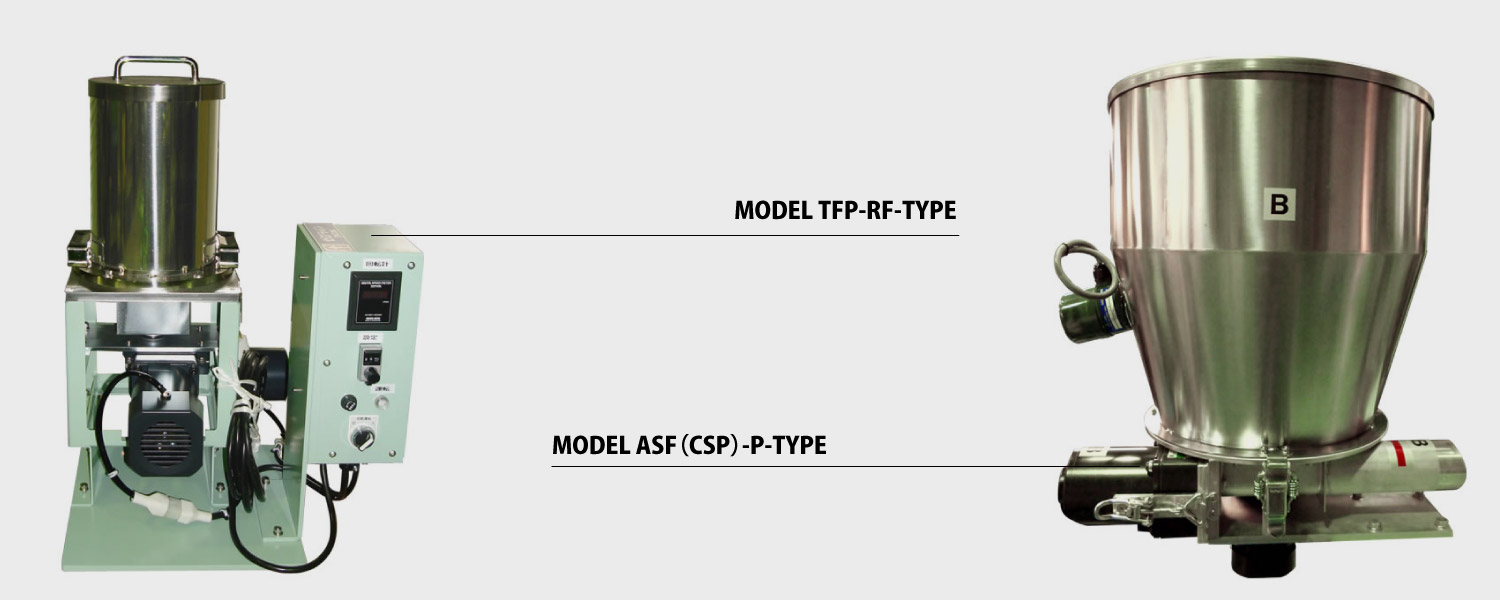

| Zero line ASF-P-TYPE | A material weighing machine that weighs granules, resin pellets, and pellet crushed particles equipped with auger screws. |

| Zero line CSF-P-TYPE |

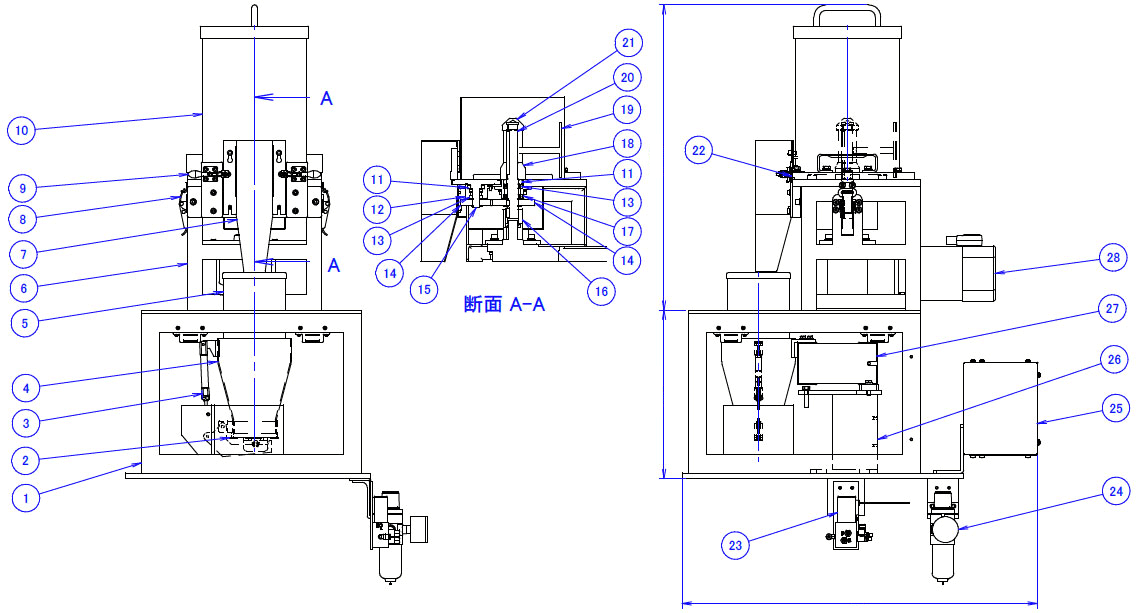

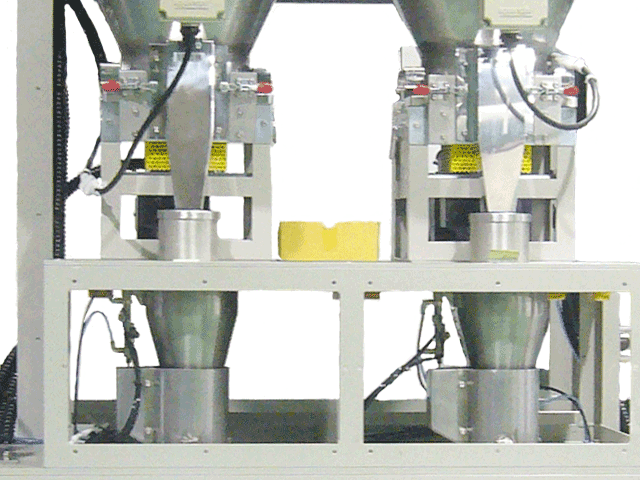

Zero line TFP-RF-TYPE

|

|

Part name

|

Part name

|

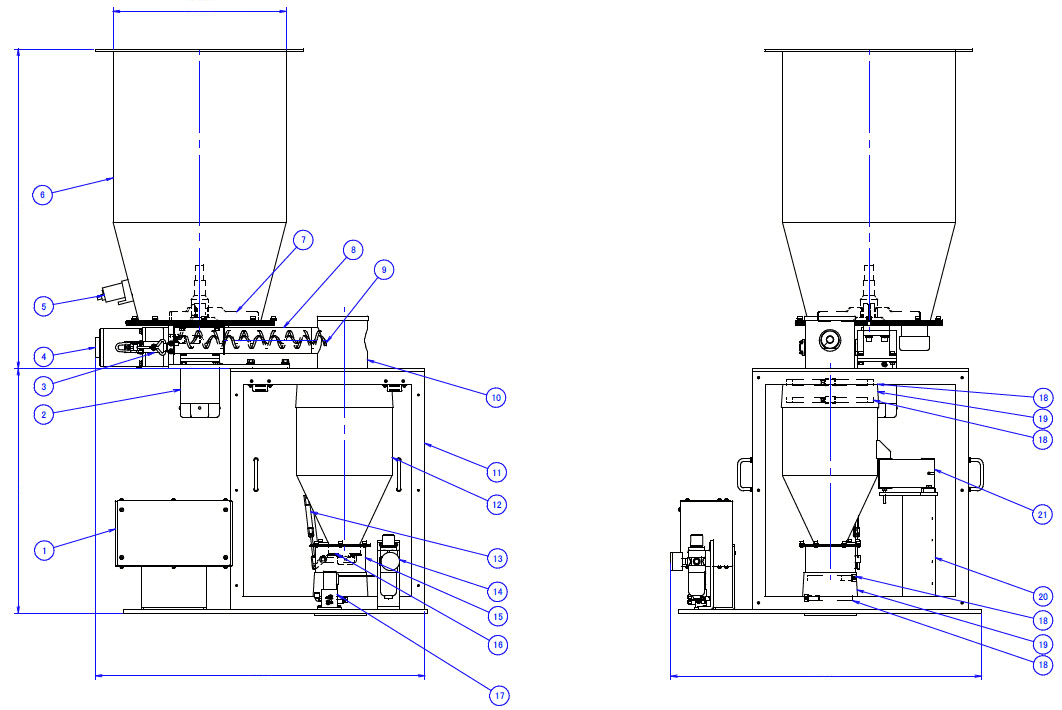

Zero line ASF-P-TYPE

|

|

Part name

|

Part name

|

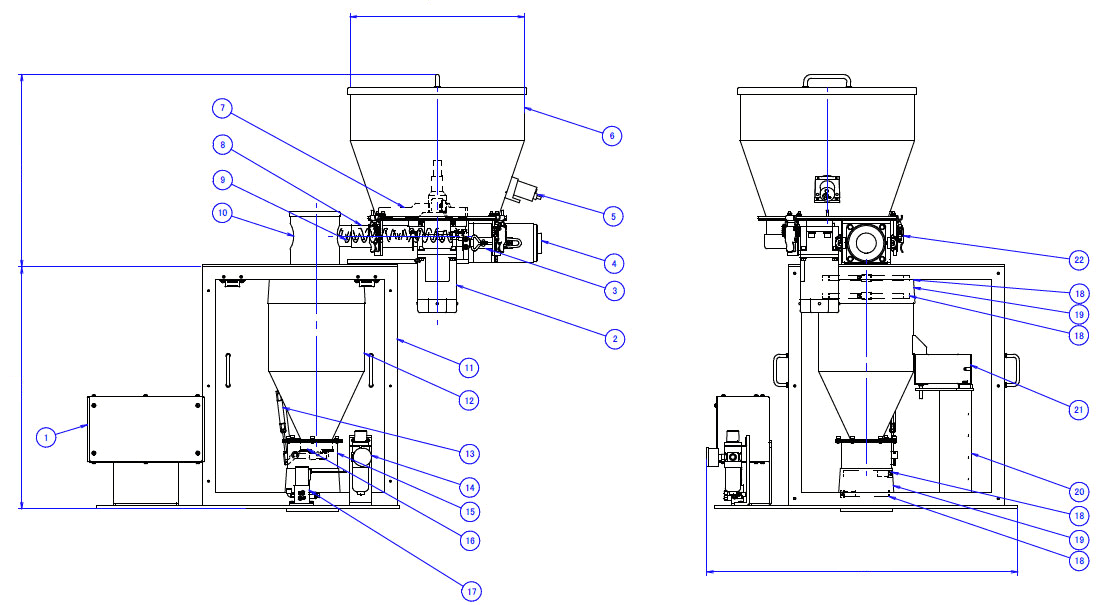

Zero line CSF-P-TYPE

|

|

Part name

|

p[c¼

|

specification

|

Power consumption | AC200V / 100V 50 / 60Hz |

| Weighing ability | 50g, 250g, 500g, 990g, 5000g etc. | |

| Metrology system | } 0.5% FS | |

| Mechanical dimensions | 300D * 400H, 400D * 600H, and more |

Original special feeder

| Original special feeder | |||

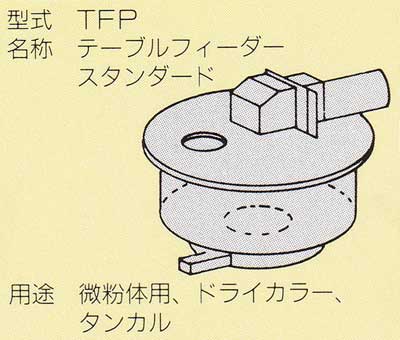

| Format TFP Table feeder standard Use For fine powder, dry color, tanker |

|

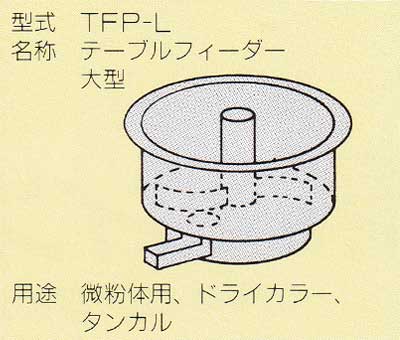

Format TFP-L Large table feeder Use For fine powder, dry color, tanker |

|

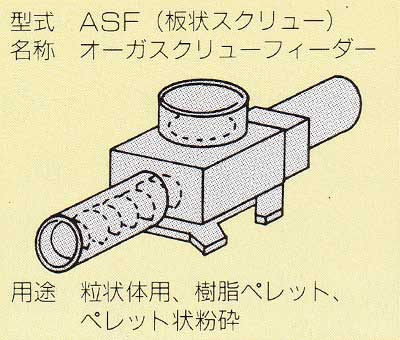

| Type ASF (plate screw) Auger screw feeder Use For granules, resin pellets, pellet crushing |

|

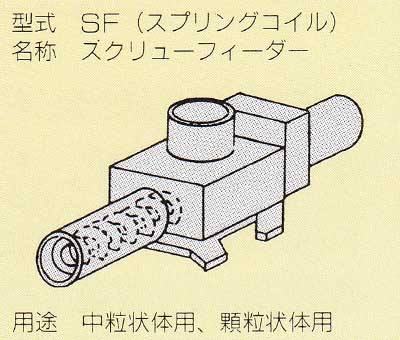

Type SP (spring coil) Screw feeder Use For medium granules / granules |

|

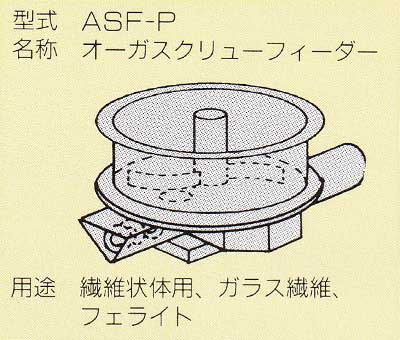

| Format ASF-P Auger screw feeder Use Granular material feeder with poor fluidity |

|

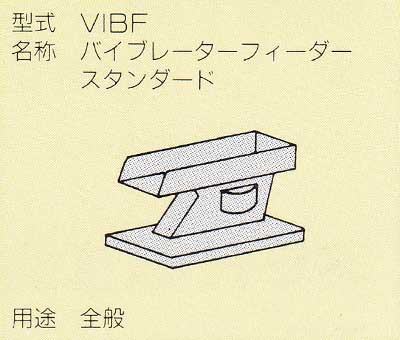

Format VIBF Vibrator feeder standard Use General / Granular / Resin pellets |

|

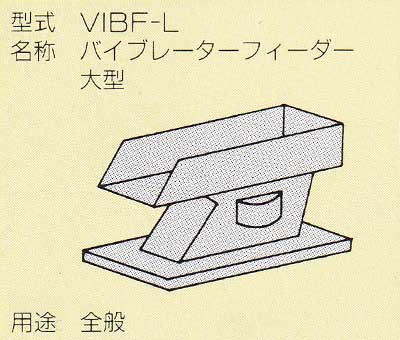

| Format VIBF-L Large vibrator feeder Use For general / granules / resin pellets |

|

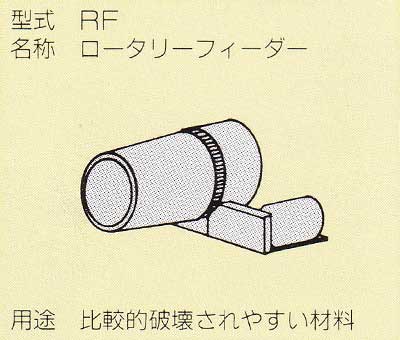

Format RF Rotary feeder Use Materials that are relatively fragile |

|

Original production and customization by combining with other models is also possible according to your company's request. We will design the weighing device according to your factory equipment.